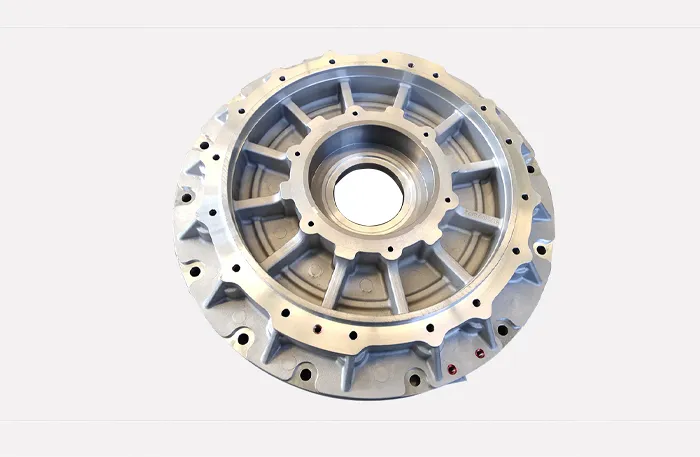

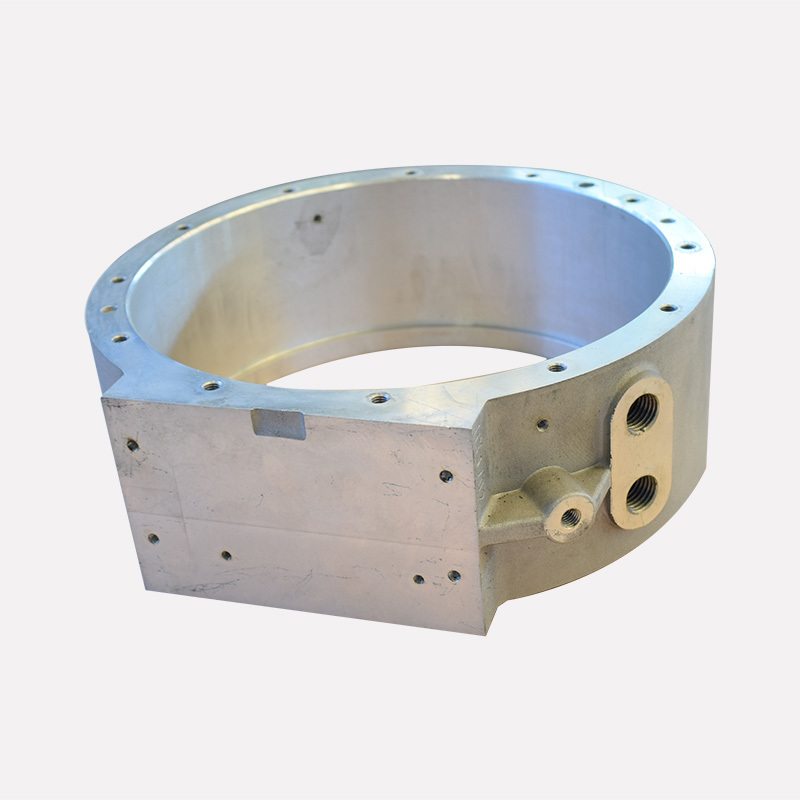

Product Display

The company is committed to the development, production and service of high-performance aluminum alloy casting parts, marine (water heater) anti-corrosion products, the company has now formed an annual output of 300,000 sets of high-end aluminum alloy casting automotive parts, 10,000 tons of sacrificial anode products and 3,000 tons of aluminum alloy, magnesium alloy profiles products production capacity.

Aluminum Parts

Light weight: The lower density of aluminum alloy makes the aluminum alloy motor housing lighter than traditional iron or cast iron motor housings, making it easier to install and transport.

Inquiry

Inquiry

Casting process: It is suitable for large and complex shell structure, with good mechanical properties and dimensional stability, commonly used in the manufacture of heavy-duty gearbox shells.

Inquiry

Inquiry

sacrificial Anode

Sacrificial anode is a technology that utilizes the principle of electrochemical primary cell for metal corrosion protection. The basic principle is to connect the metal with negative potential (called sacrificial anode) with the protected metal structure to form a primary cell system.

Inquiry

Inquiry

Sacrificial anode is a technology that utilizes the principle of electrochemical primary cell for metal corrosion protection. The basic principle is to connect the metal with negative potential (called sacrificial anode) with the protected metal structure to form a primary cell system.

Inquiry

Inquiry

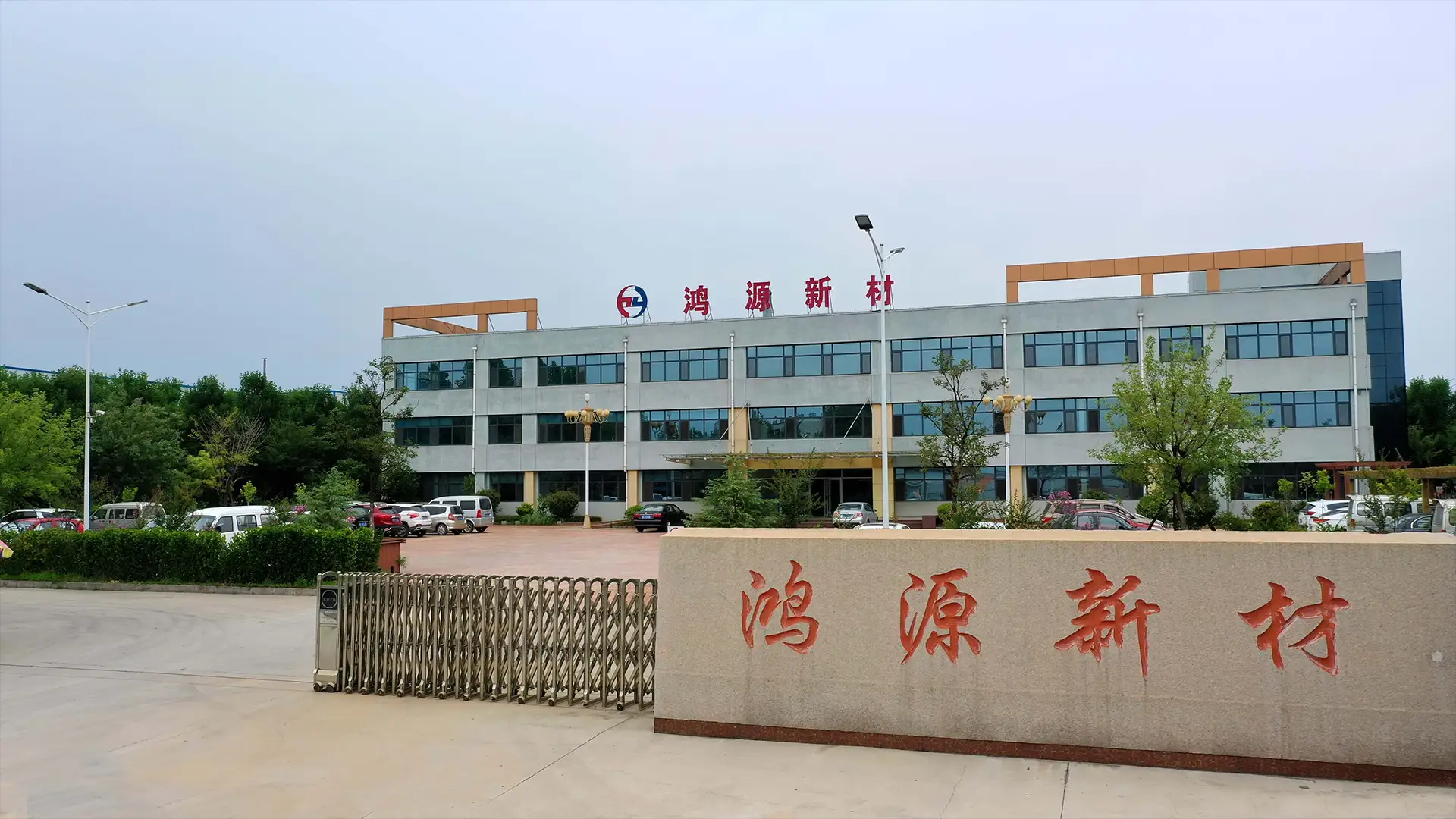

Production

Production Capacity

Innovation-driven, efficient production

Hongyuan New Materials is committed to the development, production and service of high-performance aluminum alloy casting parts and marine (water heater) anti-corrosion products.

Quality is the basis, precision is the ruler

With spectrometer, X-ray flaw detection, three-coordinate standard, air tightness testing, dynamic balance and other quality testing equipment and testing capabilities.

The original heart will not change, the quality will not be forgotten

More than 10 years of persistence and stormy journey, we never stop, the company has passed the IATF16949, ISO9001, ISO14001, ISO18001 and other management systems.

Cast the brand, create the future

With the spirit of excellence, casting each precision parts, we firmly believe that the quality of casting brand, craftsmanship cast the future!

WHY CHOOSE US?

Our Advantages

Equipment Advantage

Meanwhile, we have perfect supporting production capacity of core making, casting, heat treatment, CNC machining and so on;

Capacity Advantage

The company has now formed an annual production capacity of 300,000 sets of high-end aluminum alloy casting auto parts, 10,000 tons of sacrificial anode products and 3,000 tons of aluminum alloy and magnesium alloy profiles.

Quality Advantage

We have quality testing equipments and testing ability such as spectrometer, X-ray flaw detection, three-coordinate standard, air tightness testing, dynamic balance, etc. The company has passed IATF16949, ISO9001, ISO14001, ISO18001 and other management systems.

Service Advantages

Our company has established a long-term and stable cooperative relationship with ABB, Wolong ZF, UNIC, Aipure, Shanghai Siyuan Electric, China CNR, AVIC, Gree Electric Appliances, Yutong Automobile, Weichai Power, Yuchai, CNOOC, China Communications Construction, Steel Research Nacke, Sunrise Oriental, and other domestic and foreign high-quality customers' supporting suppliers.

About Hong Yuan

HONGYUAN

Since

2012

For many years, we have been providing you with high-performance aluminum alloy casting parts, marine anti-corrosion products

Shandong Hongyuan New Material Co., Ltd. was established in 2012, located in Yuezhuang Industrial Park, Yiyuan County, Shandong Province; the company covers an area of more than 30,000 square meters, with a registered capital of 30 million yuan; the company is committed to high-performance aluminum alloy casting parts, marine (water heater) corrosion-resistant products development, production and services, the company has now formed an annual production capacity of 300,000 sets of high-end aluminum alloy casting automotive parts, 10,000 tons of sacrificial anode products and 3 The company now has an annual output of 300,000 sets of high-end aluminum alloy casting auto parts, 10,000 tons of sacrificial anode products and 3,000 tons of aluminum alloy and magnesium alloy profiles.

Found In

Footprint

High-end aluminum alloy casting auto parts annual output

Blog

Get a Free Consultancy

Please leave your contact information and we will arrange for an expert to contact you.

2024-10-30

2024-10-30