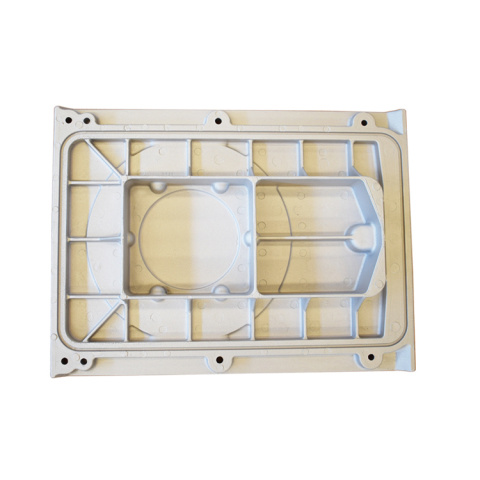

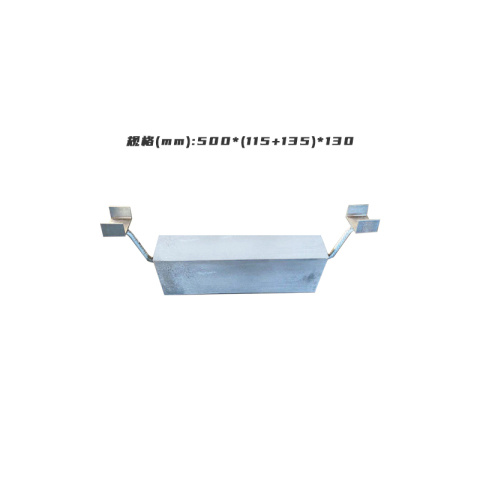

Transmission and transformation

Key words:

Transmission and transformation

Classification:

- Details

-

Aluminum alloy power parts are various components and assemblies used in power systems that are made using aluminum alloy materials. Aluminum alloys are widely used in the power industry because of their excellent physical and mechanical properties.

Physical and Mechanical Properties of Aluminum Alloys

Aluminum alloy is a material made by alloying aluminum with other elements (e.g. copper, zinc, magnesium, etc.). It has the following main properties:

Lightweight: the density of aluminum alloy is about 2.7g/cm³, which is only one-third of that of iron, which gives it a significant advantage in weight reduction.

High strength: the strength of aluminum alloys can be significantly increased by alloying, with some alloys having a tensile strength of up to 2460 kgf/mm², close to or exceeding that of high-quality steel.

Good plasticity and corrosion resistance: Aluminum alloys are easy to machine into a variety of shapes and perform well in wet and corrosive environments.

Excellent electrical and thermal conductivity: This makes aluminum alloys excellent for power transmission and heat dissipation.

Advantages of Aluminum Alloy Power Parts

Reduced weight: The low density of aluminum alloys significantly reduces the overall weight of electrical equipment, lowering transportation and installation costs.

Improved efficiency: Good electrical and thermal conductivity helps improve power transmission and conversion efficiency.

Corrosion resistance: Aluminum alloy has good corrosion resistance, extending the service life of the equipment.

Good processing performance: aluminum alloy is easy to process into various shapes and sizes, adapting to complex manufacturing needs.

Leave A Message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.

Related Products

Aluminum Alloy Parts

New Energy Vehicle

Electric Power Series

-

Conductor

Aluminum alloy power parts are various components and assemblies used in power systems that are made using aluminum alloy materials. Aluminum alloys are widely used in the power industry because of their excellent physical and mechanical properties.

-

Contactors

High strength: the strength of aluminum alloys can be significantly increased by alloying, with some alloys having a tensile strength of up to 2460 kgf/mm², close to or exceeding that of high-quality steel.

-

Electric power series

Good plasticity and corrosion resistance: Aluminum alloys are easy to machine into a variety of shapes and perform well in wet and corrosive environments.

-

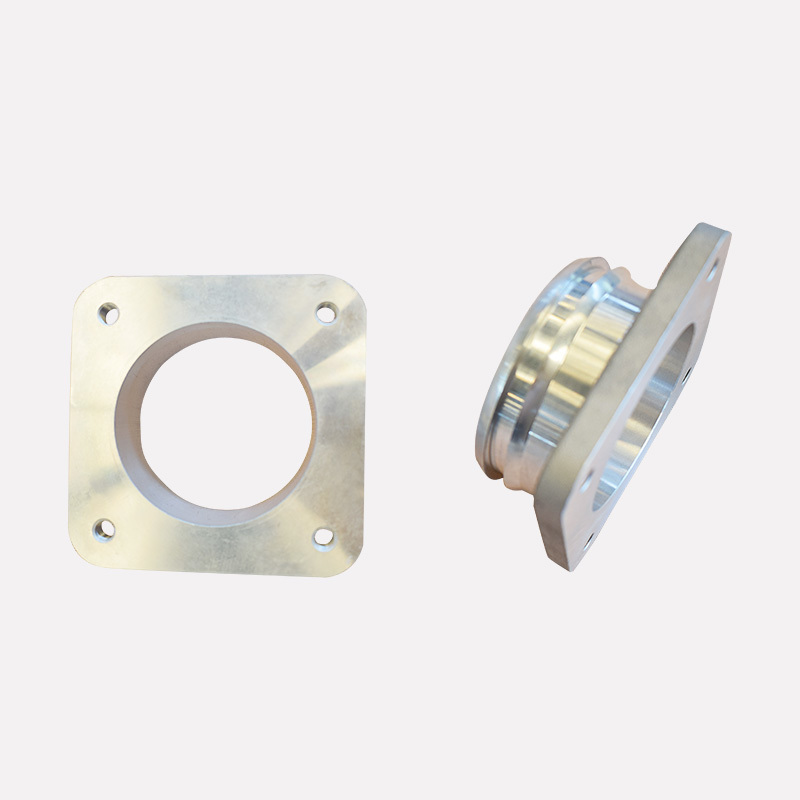

Flanged

Good plasticity and corrosion resistance: Aluminum alloys are easy to machine into a variety of shapes and perform well in wet and corrosive environments.

-

Armature box

Reduced weight: The low density of aluminum alloys significantly reduces the overall weight of electrical equipment, lowering transportation and installation costs.

-

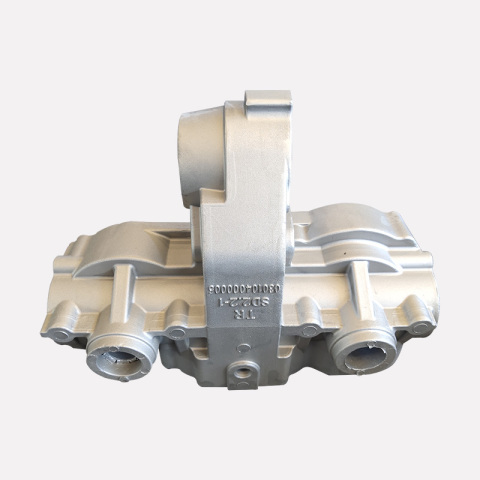

Transmission and transformation

Improved efficiency: Good electrical and thermal conductivity helps improve power transmission and conversion efficiency.

-

Oil conservator

Good plasticity and corrosion resistance: Aluminum alloys are easy to machine into a variety of shapes and perform well in wet and corrosive environments.

-

Oil tank

Good processing performance: aluminum alloy is easy to process into various shapes and sizes, adapting to complex manufacturing needs.

Industry Equipment

-

Industrial accessories

Lightweight: Aluminum alloy materials are lightweight and high-strength, which can reduce the weight of the overall structure and improve the load-bearing capacity.

-

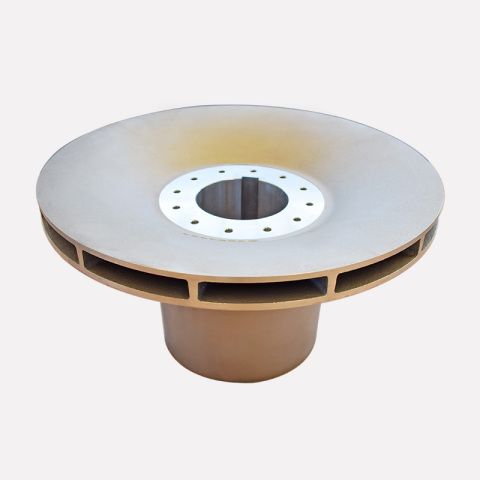

Wind fan

Easy to install: with modular design, it is easy and convenient to install without complicated process and tools, which improves the construction efficiency.

-

Turbine wheel

Flexibility: a wide variety of types can be combined and matched according to different needs, realizing a variety of complex structures and functions.

-

Snail's shell

Flexibility: a wide variety of types can be combined and matched according to different needs, realizing a variety of complex structures and functions.

-

Snail shell

Easy to install: with modular design, it is easy and convenient to install without complicated process and tools, which improves the construction efficiency.

-

Snail shell

Lightweight: Aluminum alloy materials are lightweight and high-strength, which can reduce the weight of the overall structure and improve the load-bearing capacity.

Auto Parts

Other parts

-

Other accessories

Mechanical industry: Aluminum alloy fittings are widely used in the structural parts of various mechanical equipments, such as airplanes, automobiles, trains, ships and so on.

-

Other accessories

Electronic industry: Aluminum alloy fittings are also widely used in the shells, radiators and accessories of electronic equipment. Aluminum alloy has good heat dissipation performance, which can effectively reduce the temperature of electronic equipment and improve its operating efficiency and life.

-

Other accessories

Electronic industry: Aluminum alloy fittings are also widely used in the shells, radiators and accessories of electronic equipment. Aluminum alloy has good heat dissipation performance, which can effectively reduce the temperature of electronic equipment and improve its operating efficiency and life.

-

Oil filter

High strength: Compared with ordinary aluminum, aluminum alloy has higher strength, better corrosion resistance and fatigue life, and can withstand greater tensile or compressive forces.

-

Other accessories

Easy processing: aluminum alloy has good plasticity and formability, which can be processed into desired shapes by various methods, and at the same time, it can also reduce production costs.

-

Aluminum handle

Easy to recycle: aluminum alloy material has the characteristic of recyclability, which can effectively reduce the pollution to the environment and also has economic benefits.

-

Other accessories

Aluminum alloy has good heat dissipation performance, which can effectively reduce the temperature of electronic equipment and improve its operating efficiency and life.

-

Subway seat end plate

High strength: Compared with ordinary aluminum, aluminum alloy has higher strength, better corrosion resistance and fatigue life, and can withstand greater tensile or compressive forces.

-

Other accessories

Lightweight: Compared with other metal materials, aluminum alloy is a relatively lightweight material, which can reduce the weight of the equipment, increase the operating efficiency of the equipment and reduce the fuel consumption of the vehicle.

-

Other accessories

Electronic industry: Aluminum alloy fittings are also widely used in the shells, radiators and accessories of electronic equipment. Aluminum alloy has good heat dissipation performance, which can effectively reduce the temperature of electronic equipment and improve its operating efficiency and life.

-

Other accessories

Easy processing: aluminum alloy has good plasticity and formability, which can be processed into desired shapes by various methods, and at the same time, it can also reduce production costs.

-

Other accessories

Lightweight: Compared with other metal materials, aluminum alloy is a relatively lightweight material, which can reduce the weight of equipment, increase the operating efficiency of equipment and reduce the fuel consumption of vehicles.

-

Other accessories

Easy processing: aluminum alloy has good plasticity and formability, which can be processed into desired shapes by various methods, and at the same time, it can also reduce production costs.

-

Other accessories

Mechanical industry: Aluminum alloy fittings are widely used in the structural parts of various mechanical equipments, such as airplanes, automobiles, trains, ships and so on.

-

Other accessories

Construction industry: Aluminum alloy fittings are used in windows, door frames, curtain walls and other parts of the building structure. Compared with traditional materials, aluminum alloy is lighter, stronger and less prone to deformation, which can increase the structural strength and aesthetics of buildings.

-

Other accessories

High strength: Compared with ordinary aluminum, aluminum alloy has higher strength, better corrosion resistance and fatigue life, and can withstand greater tensile or compressive forces.

-

Other accessories

Easy processing: aluminum alloy has good plasticity and formability, which can be processed into desired shapes by various methods, and at the same time, it can also reduce production costs.

-

Pump body

Compared with traditional materials, aluminum alloy is lighter, stronger and less prone to deformation, which can increase the structural strength and aesthetics of buildings.

-

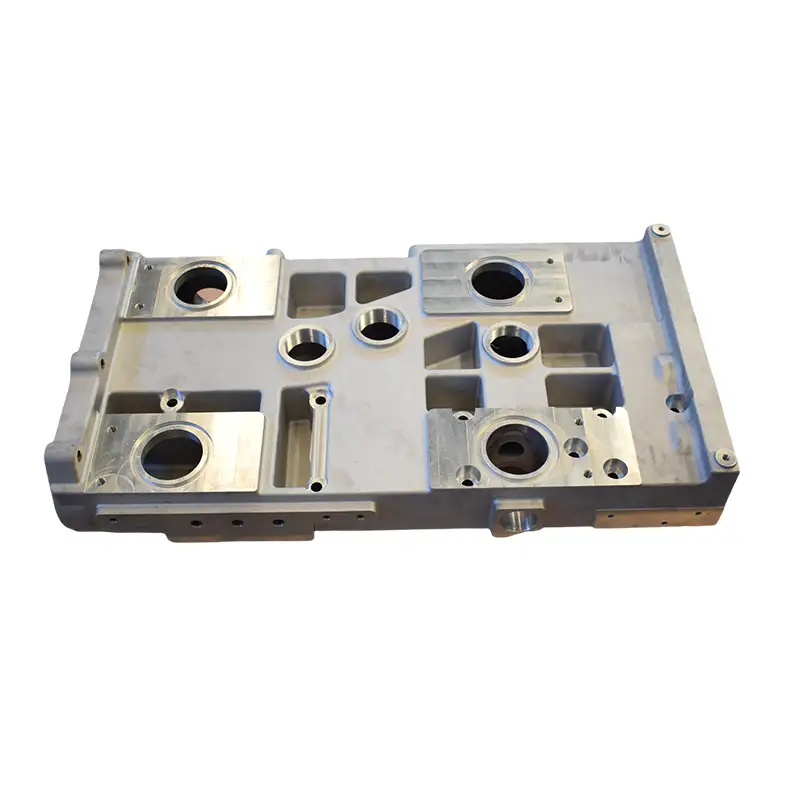

Battery enclosure

Compared with other metal materials, aluminum alloy is a relatively lightweight material, which can reduce the weight of equipment, increase the operating efficiency of equipment and reduce the fuel consumption of vehicles.

-

Heat exchanger plate

Construction industry: Aluminum alloy fittings are used in windows, door frames, curtain walls and other parts of the building structure. Compared with traditional materials, aluminum alloy is lighter, stronger and less prone to deformation, which can increase the structural strength and aesthetics of buildings.

-

Mixer core

Aluminum alloy fittings are used in windows, door frames, curtain walls and other parts of the building structure. Compared with traditional materials, aluminum alloy is lighter, stronger and less prone to deformation, which can increase the structural strength and aesthetics of buildings.

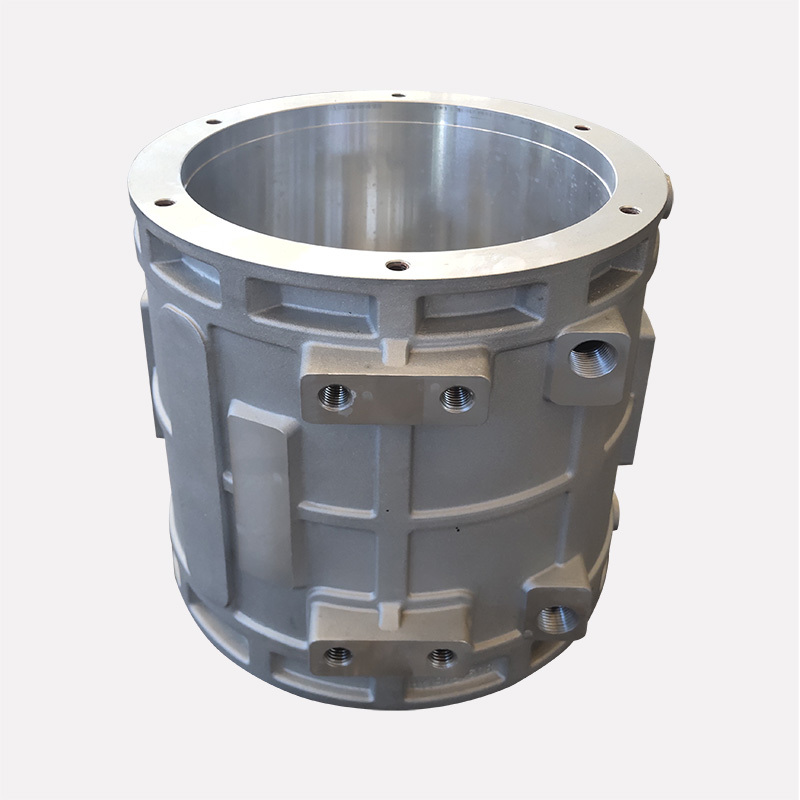

Motor Casing

-

One-piece water-cooled motor casing

The integrated water-cooled motor housing is a motor housing with an integrated cooling system, which is mainly characterized by efficient heat dissipation and compactness.

-

One-piece water-cooled motor casing

Sealing technology: Advanced sealing technology, such as O-ring, silicone gasket or sealant, ensures that the coolant will not leak and improves the reliability of the motor.

-

One-piece water-cooled motor casing

Material selection: usually use good thermal conductivity of metal materials, such as aluminum alloy, stainless steel or copper, these materials not only have good thermal conductivity, but also corrosion resistance.

-

One-piece water-cooled motor casing

Material Selection: Usually good thermal conductivity of metal materials, such as aluminum alloy, stainless steel or copper, these materials not only have good thermal conductivity, but also have corrosion resistance.

-

One-piece water-cooled motor casing

Precision processing and testing: CNC numerical control processing technology and friction welding technology are adopted to ensure the accuracy of each part of the shell, and the airtightness and reliability are checked by non-destructive testing means (e.g. ultrasonic testing, pressure testing, etc.).

-

One-piece water-cooled motor housing

Industrial automation equipment: In the factory automation production line, the motor needs to run efficiently for a long time, the water-cooled motor housing can provide stable heat dissipation to ensure the stable operation of the equipment.

-

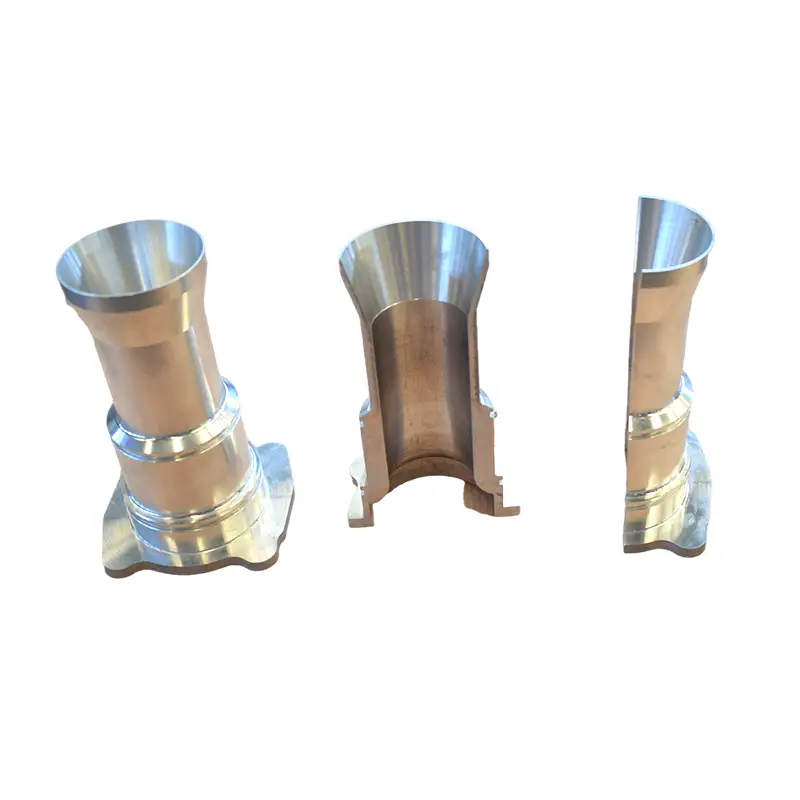

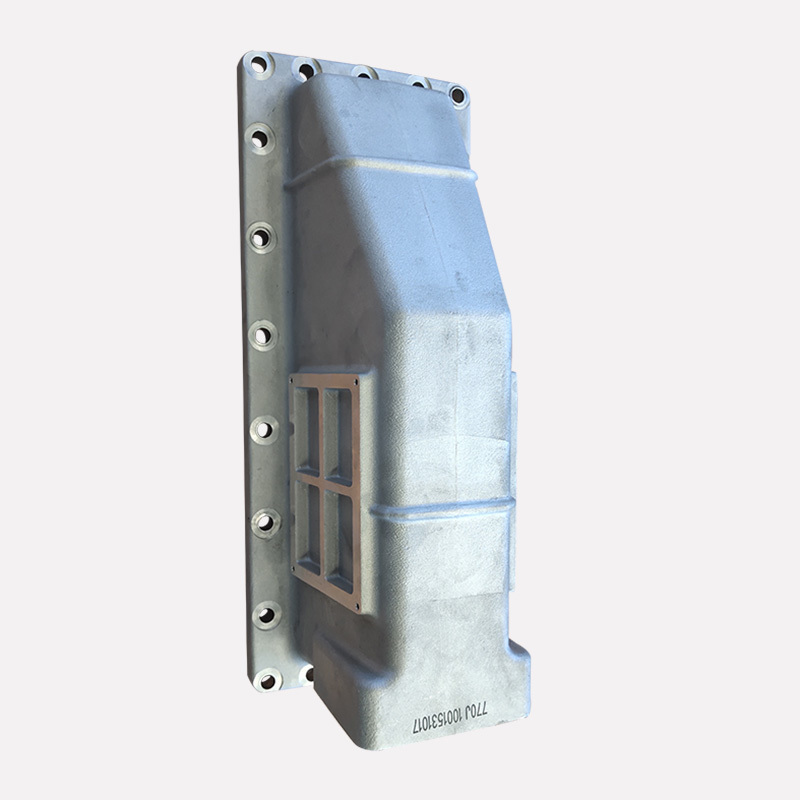

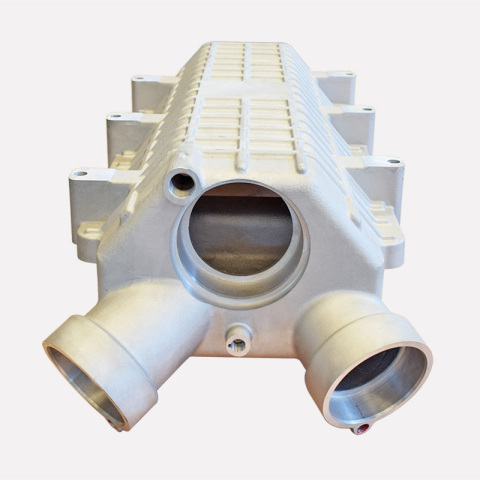

Intercooler housing

Aluminum intercooler housing is an important accessory for turbocharged engine, the main role is to reduce the temperature of the air after supercharging, so as to reduce the heat load of the engine, improve the efficiency of air exchange, and increase the output power of the engine.

-

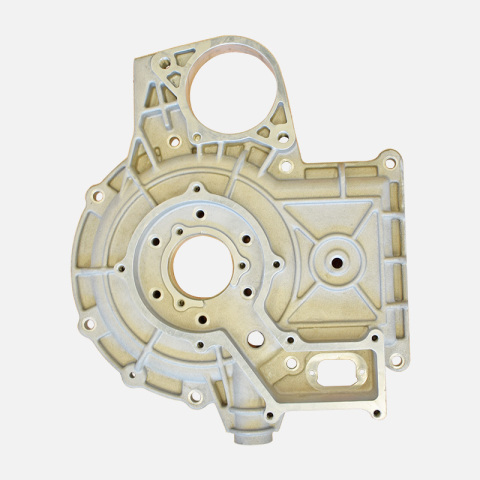

Motor housing

Light weight: The lower density of aluminum alloy makes the aluminum alloy motor housing lighter than traditional iron or cast iron motor housings, making it easier to install and transport.

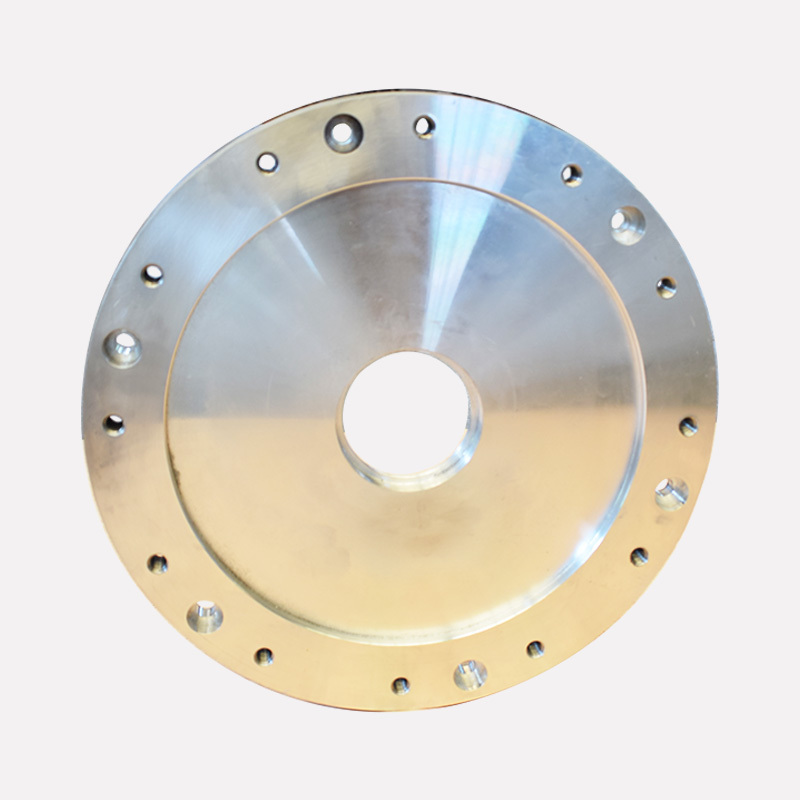

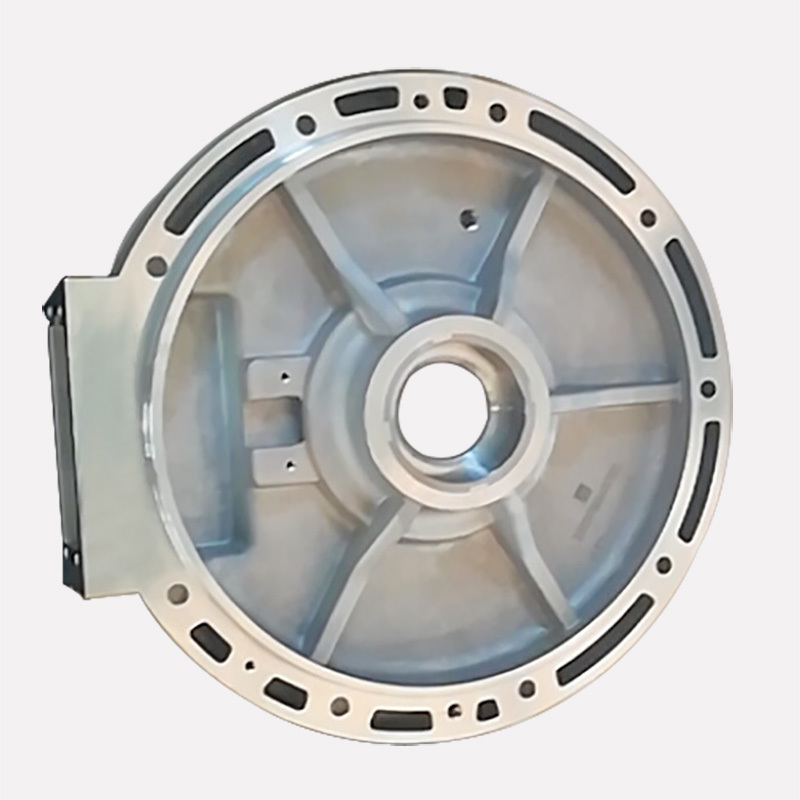

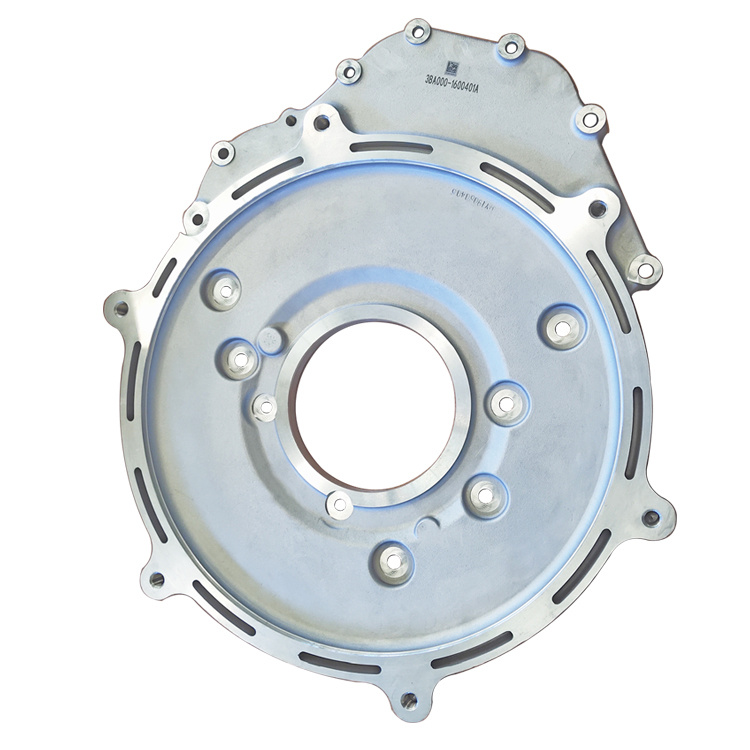

End Cap

-

End cap

Lightweight: Aluminum alloy is less dense and lighter, which can significantly reduce the overall weight of the vehicle, thus improving fuel economy and vehicle handling performance.

-

End cap

Aluminum alloy end caps are commonly used in high-temperature components such as engines and radiators in automobiles, and their lightweight design helps reduce the overall weight of the vehicle, thereby improving fuel economy and performance.

-

End cap

Strength and Rigidity: Despite its low density, aluminum alloy has high strength and rigidity and is able to withstand large external forces and impacts to ensure the safety performance of the car.

-

End cap

Corrosion resistance: Aluminum alloy has good corrosion resistance and can maintain better performance in wet environments, prolonging the service life of parts.

-

End cap

Corrosion resistance: Aluminum alloy has good corrosion resistance, which can maintain better performance in wet environment and prolong the service life of parts.

-

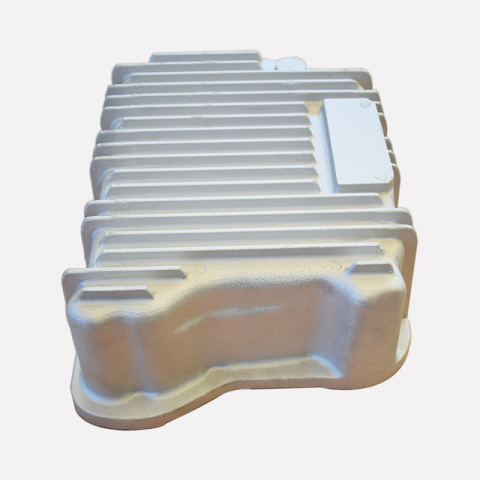

Oil sump

Lightweight: Aluminum alloy is less dense and lighter, which can significantly reduce the overall weight of the vehicle, thus improving fuel economy and vehicle handling performance.

-

Rear end cap

Strength and Rigidity: Despite its low density, aluminum alloy has high strength and rigidity, which can withstand large external forces and impacts and ensure the safety performance of the car.

-

Rear end cap of the center car

Corrosion resistance: Aluminum alloy has good corrosion resistance and can maintain better performance in wet environments, prolonging the service life of parts.

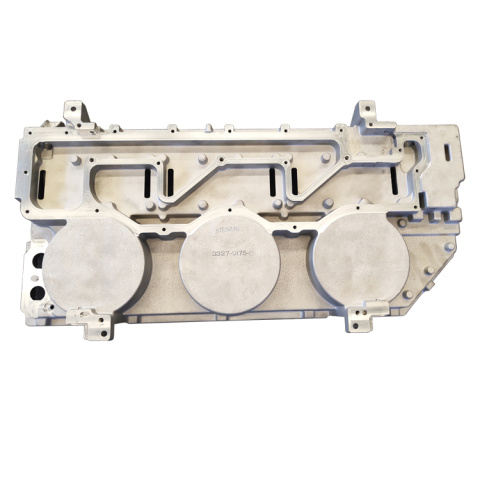

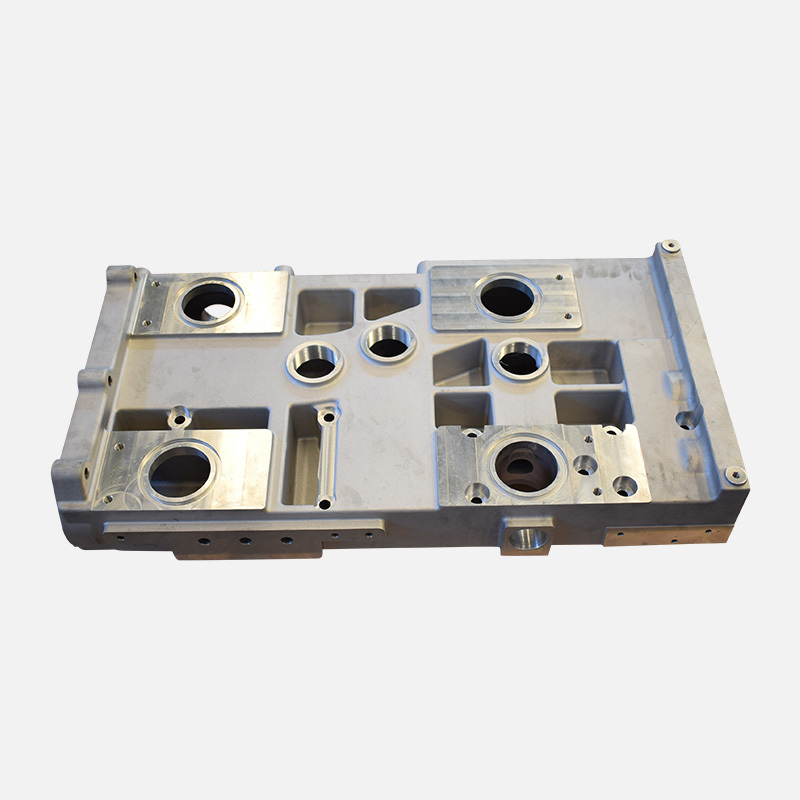

Transmission

-

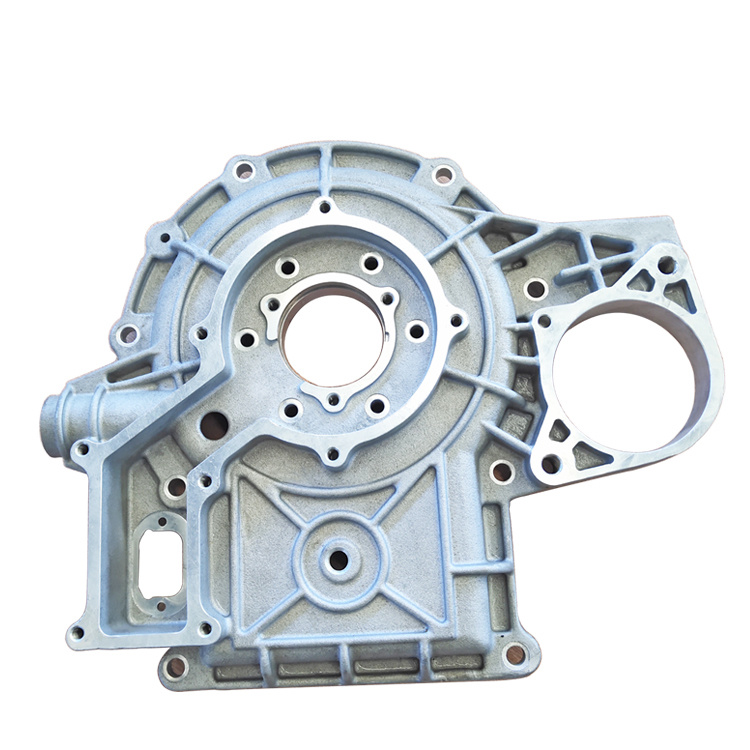

Distributor housing

Aluminum alloy transmission housing is a commonly used component in modern automobile manufacturing, mainly used to carry and protect the mechanical parts inside the transmission to ensure its normal operation.

-

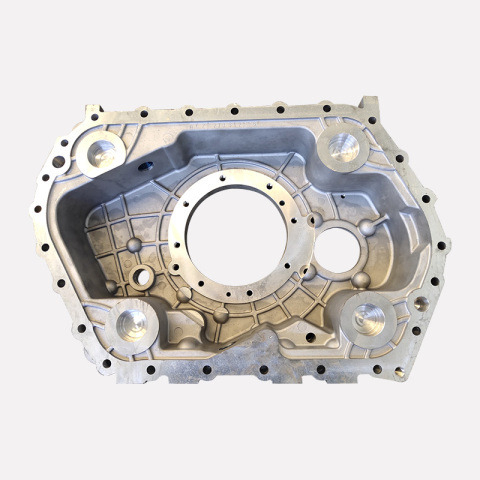

Transmission

Casting process: It is suitable for large and complex shell structure, with good mechanical properties and dimensional stability, commonly used in the manufacture of heavy-duty gearbox shells.

-

Transmission

Die casting process: Molten aluminum alloy is injected into the mold through high pressure to form a shell with high precision and high surface quality. Die casting aluminum alloy is high strength, light weight and dimensionally stable, which makes it suitable for manufacturing complex shaped gearbox housings.

-

Transmission

High-performance aluminum alloy: such as 6061 aluminum alloy and 7075 aluminum alloy, commonly used in the field of new energy vehicles. These materials have higher strength and better corrosion resistance, ensuring performance while reducing weight and improving energy efficiency.

-

Transmission

5052 aluminum plate: lightweight, easy to process, corrosion resistance and environmental protection advantages. 5052 aluminum plate is suitable for automotive lightweighting needs, high elongation, easy to stamping and welding, strong resistance to marine atmospheric corrosion, and high recycling rate.

-

Turbocharger housings

ADC12 die-casting aluminum alloy: belonging to Al-Si-Cu series, with silicon content between 9.6% and 12.0%, it has excellent casting and pressure resistance, and is suitable for manufacturing complex castings. Its high strength, good pressure resistance, thermal brittleness is small, but the corrosion resistance is slightly worse.

-

Transmission rear housing

Mechanical industry: Aluminum alloy fittings are widely used in the structural parts of various mechanical equipments, such as airplanes, automobiles, trains, ships and so on.

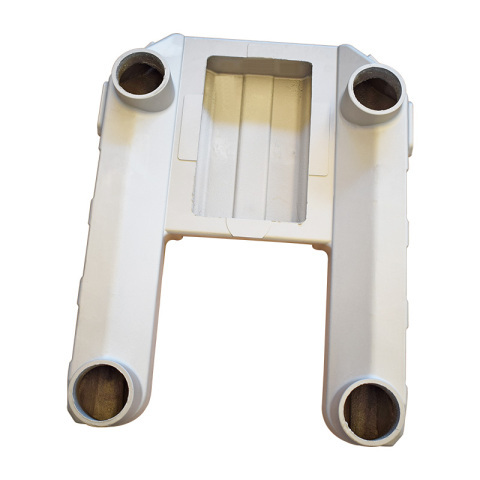

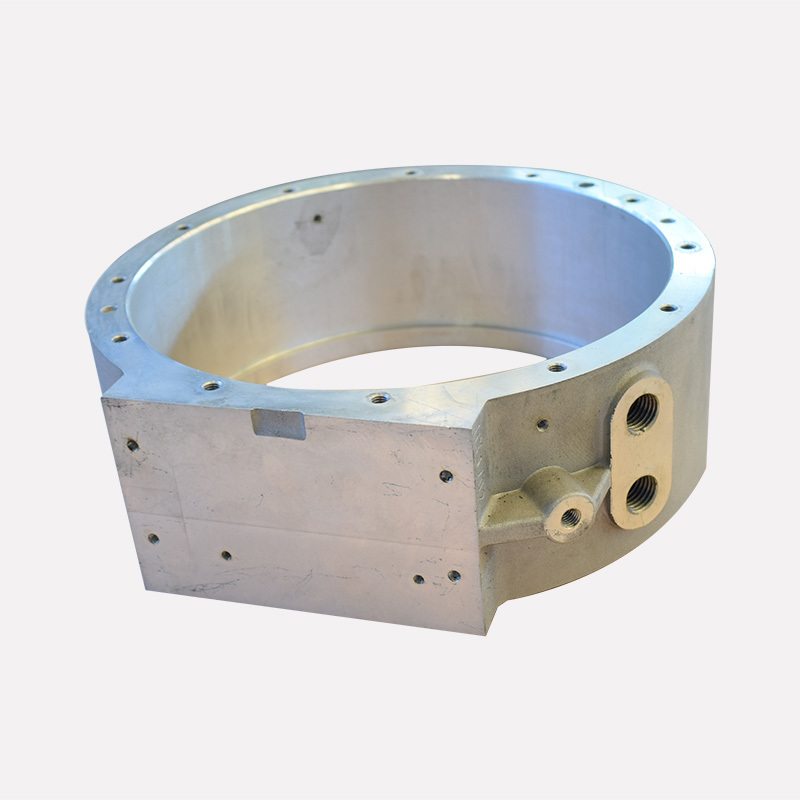

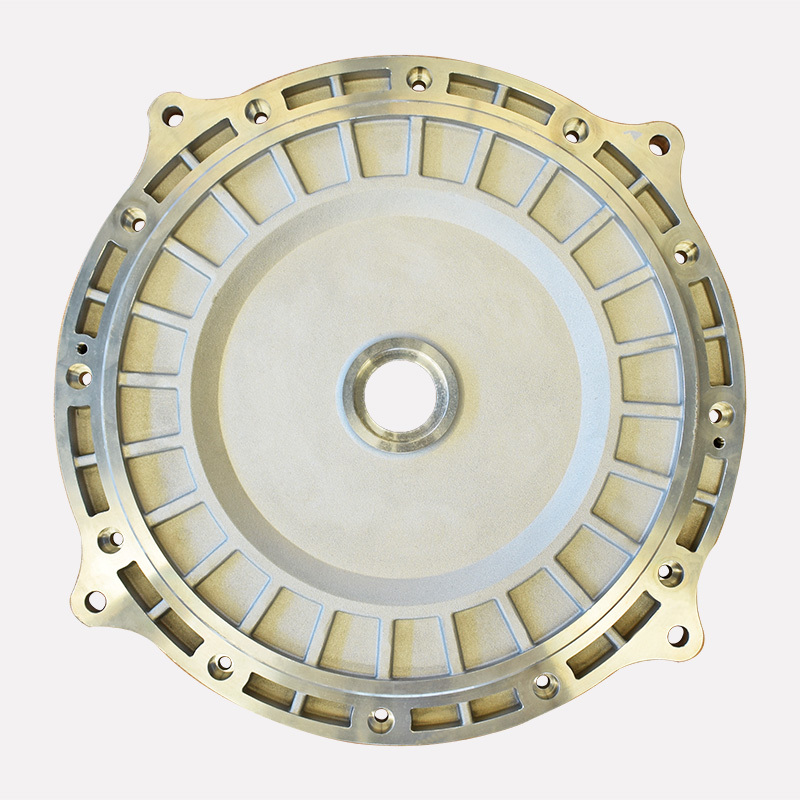

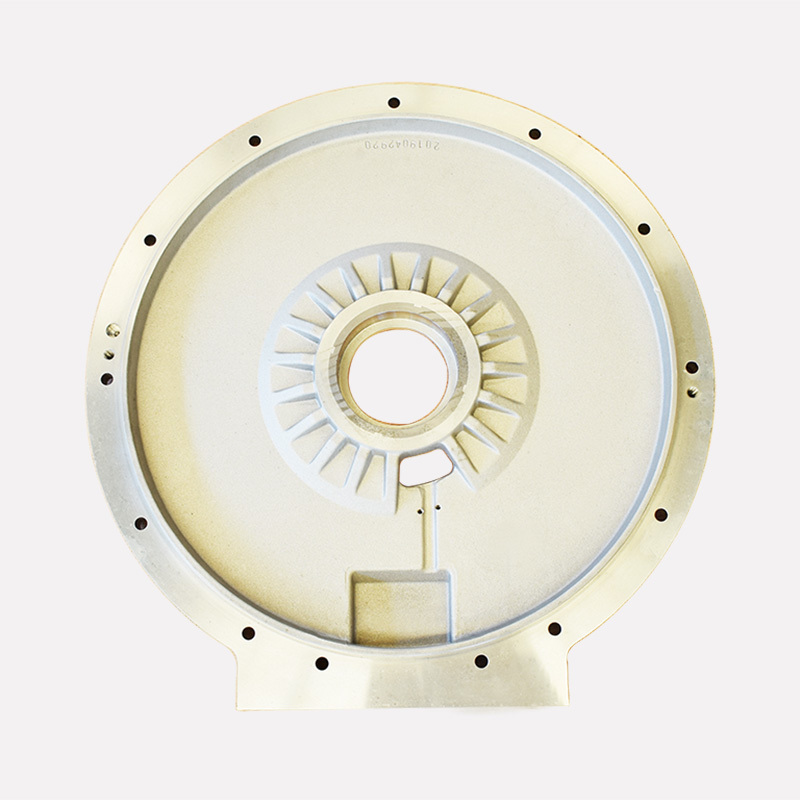

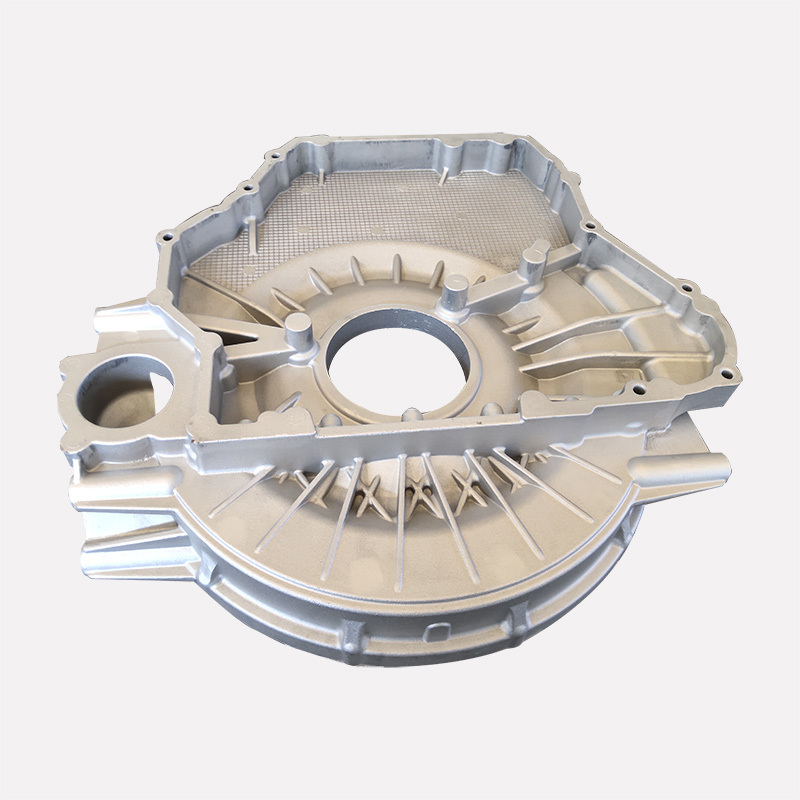

Flywheel Shell

-

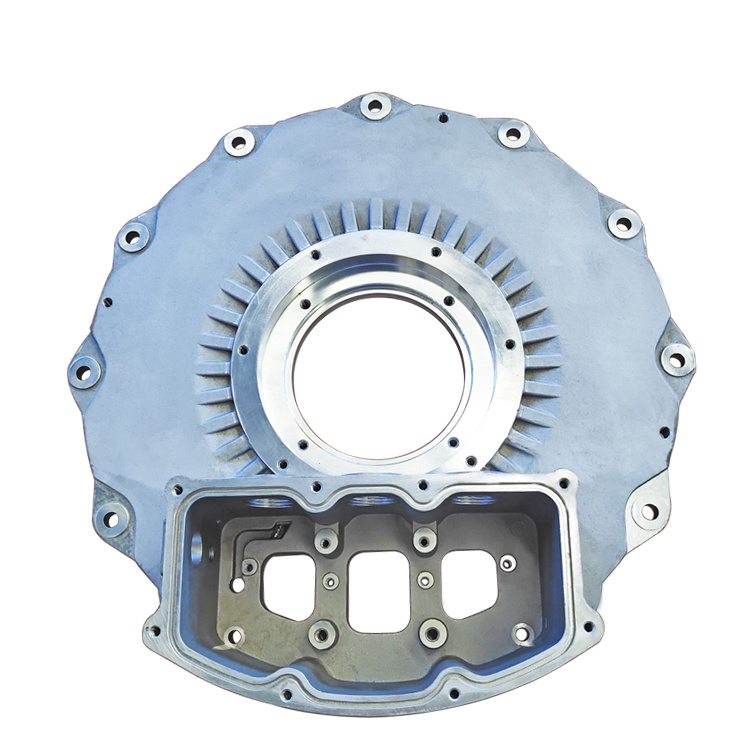

Flywheel shell

Aluminum alloy flywheel shell is a kind of mechanical parts made of aluminum alloy, mainly used to cover the flywheel and clutch outside, play a protective and supportive role.

-

Flywheel shell

Aluminum end caps are typically used in high-temperature components such as engines and radiators in automobiles, and their lightweight design helps to reduce the overall weight of the vehicle, thereby improving fuel economy and performance.

-

Flywheel shell

Heat dissipation performance: Aluminum alloy has excellent thermal conductivity and can quickly dissipate heat to ensure the normal operation of high temperature parts.

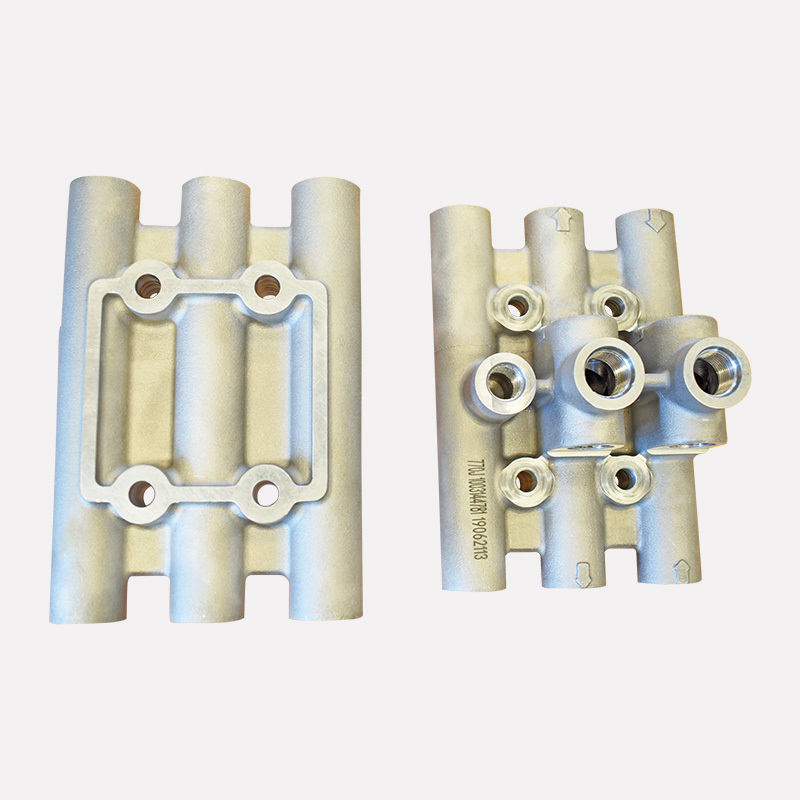

Tube Fitting Connectors

-

Tube Fittings

Industrial piping system: in petrochemical, metallurgy, mining and other industrial fields, aluminum alloy pipe fittings are used to connect all kinds of process pipelines to ensure stable transmission of fluids or gases.

-

Tube Fittings

Industrial piping system: in petrochemical, metallurgy, mining and other industrial fields, aluminum alloy pipe fittings are used to connect all kinds of process pipelines to ensure stable transmission of fluids or gases.

-

Tube Fittings

HVAC system: In the HVAC system, aluminum alloy pipe fittings are used to connect hot and cold water pipelines to ensure the normal operation of the heating and cooling system.

-

Tube Fittings

Light weight and high strength: aluminum alloy material has high strength and low density, which is easy to carry and install.

-

Tube Fittings

Water Supply and Drainage System: In the building water supply and drainage system, aluminum alloy pipe fittings are used to connect all kinds of water pipes to ensure the smooth flow of water.

-

Tube Fittings

Industrial piping system: in petrochemical, metallurgy, mining and other industrial fields, aluminum alloy pipe fittings are used to connect all kinds of process pipelines to ensure stable transmission of fluids or gases.

Other

-

Oil sump

Construction industry: Aluminum alloy fittings are used in windows, door frames, curtain walls and other parts of the building structure. Compared with traditional materials, aluminum alloy is lighter, stronger and less prone to deformation, which can increase the structural strength and aesthetics of buildings.

-

Oil sump

Construction industry: Aluminum alloy fittings are used in windows, door frames, curtain walls and other parts of the building structure. Compared with traditional materials, aluminum alloy is lighter, stronger and less prone to deformation, which can increase the structural strength and aesthetics of buildings.

-

Intercooler end cap

Easy processing: aluminum alloy has good plasticity and formability, which can be processed into desired shapes by various methods, and at the same time, it can also reduce production costs.

-

Oil Filter Holder

Aluminum alloy fittings can reduce the weight of mechanical equipment, increase the operating efficiency of the equipment and improve the structural strength of the equipment.

-

Other accessories

High strength: Compared with ordinary aluminum, aluminum alloy has higher strength, better corrosion resistance and fatigue life, and can withstand greater tensile or compressive forces.

-

Other accessories

High strength: Compared with ordinary aluminum, aluminum alloy has higher strength, better corrosion resistance and fatigue life, and can withstand greater tensile or compressive forces.

Sacrificial Anode

Magnesium bar

-

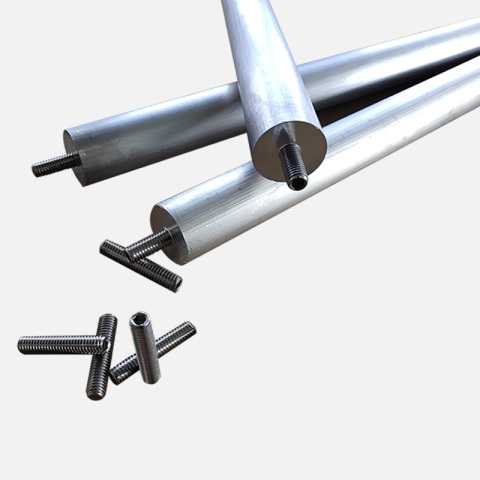

Magnesium rod

Composite magnesium rod is composed of magnesium alloy and fiber reinforced material, which has the characteristics of light weight and high strength.

-

Magnesium rod

Composite magnesium rods have good flame retardant properties, not easy to burn, so it is safer and more reliable to use in high temperature, flammable occasions.

-

Magnesium rod

Compared with traditional metal materials, composite magnesium rods can reduce the weight and improve the efficiency of the use of materials under the condition of ensuring strength.

-

Magnesium rod

Composite magnesium rod is composed of magnesium alloy and fiber reinforced material, which has the characteristics of light weight and high strength.

-

Magnesium rod assembly

Outdoor Survival: Magnesium rods are commonly used as fire-fighting equipment for outdoor survival, usually with magnesium elements as the main metal rods, able to make fire under various conditions, widely used in outdoor exploration and survival equipment.

-

Magnesium rod assembly

Electrical appliance anti-corrosion: Magnesium rods also have important applications in electrical appliance anti-corrosion technology. In water heaters, magnesium rods are used as sacrificial anodes to protect the metal liner from corrosion and extend the service life of the equipment through the principle of electrochemical corrosion prevention.

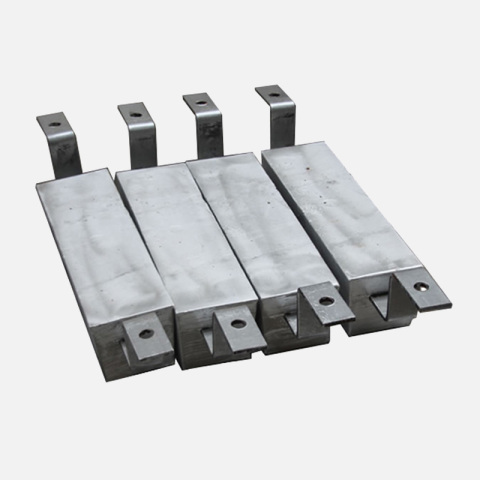

Anode block

-

Sacrificial anode

Sacrificial anode is a technology that utilizes the principle of electrochemical primary cell for metal corrosion protection. The basic principle is to connect the metal with negative potential (called sacrificial anode) with the protected metal structure to form a primary cell system.

-

Sacrificial anode

Commonly used sacrificial anode materials include magnesium, magnesium alloys, pure zinc, zinc alloys and aluminum alloys. These materials have sufficient negative potentials to corrode preferentially in the electrolyte, thereby protecting other metallic structures.

-

Sacrificial anode

Sacrificial anode is a technology that utilizes the principle of electrochemical primary cell for metal corrosion protection. The basic principle is to connect the metal with negative potential (called sacrificial anode) with the protected metal structure to form a primary cell system.

-

Sacrificial anode

In the primary cell, the sacrificial anode, as the negative pole, undergoes an oxidation reaction and is gradually consumed, thus protecting the protected metal, as the positive pole, from corrosion.

-

Sacrificial anode

Oil, petrochemical, natural gas transmission pipelines and storage tanks: prevent corrosion of pipelines and storage tanks. Harbors, bridges, ships: protect underwater and exposed metal structures. Submarine cable pipelines: protect submarine equipment from seawater corrosion.

Get a Free Consultancy

Please leave your contact information and we will arrange for an expert to contact you.