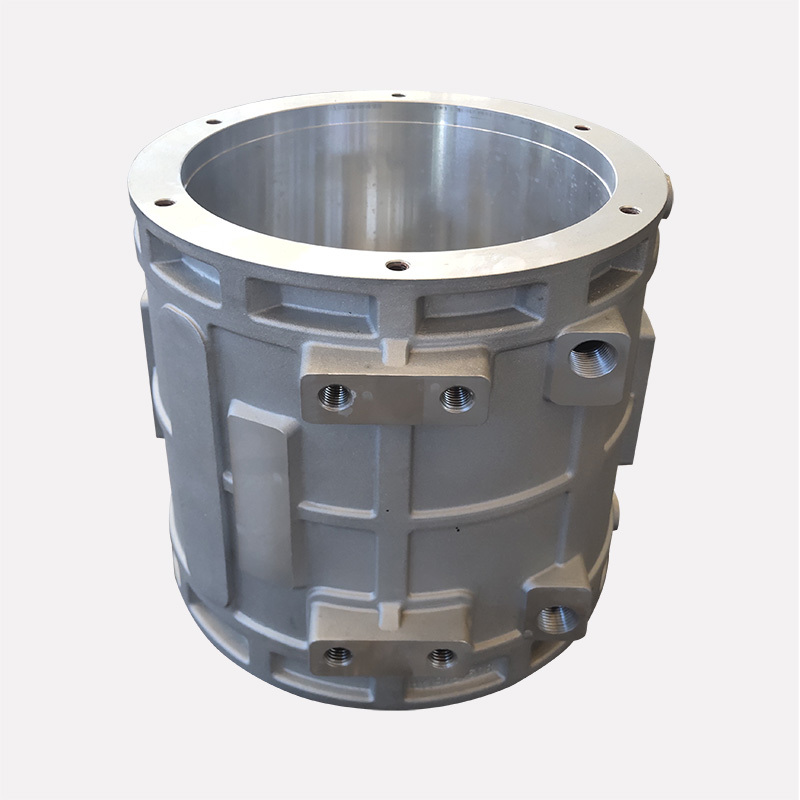

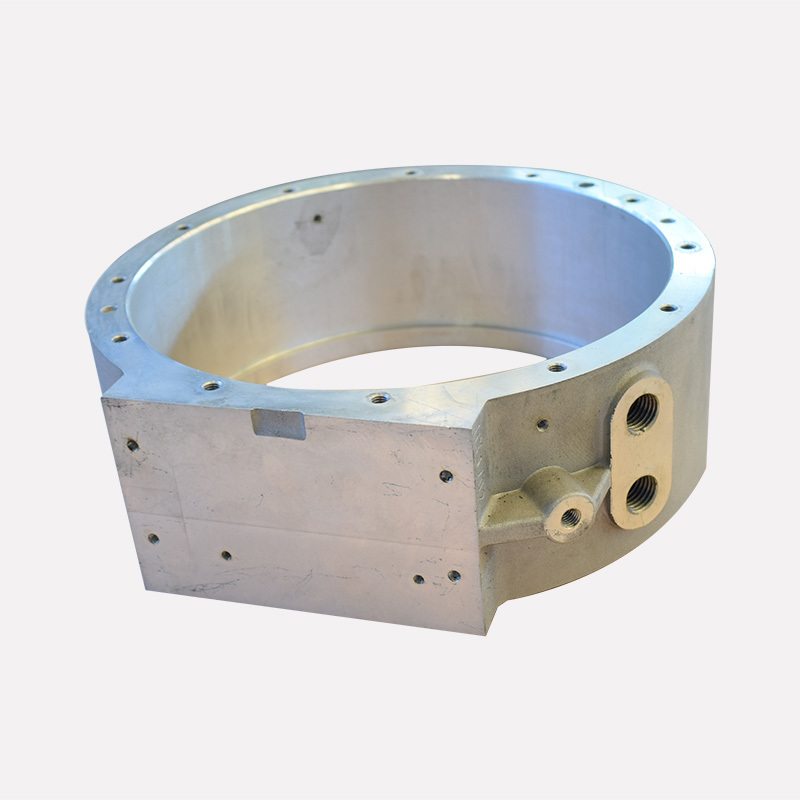

One-piece water-cooled motor casing

The integrated water-cooled motor housing is a motor housing with an integrated cooling system, which is mainly characterized by efficient heat dissipation and compactness.

Inquiry

Inquiry

One-piece water-cooled motor casing

Sealing technology: Advanced sealing technology, such as O-ring, silicone gasket or sealant, ensures that the coolant will not leak and improves the reliability of the motor.

Inquiry

Inquiry

One-piece water-cooled motor casing

Material selection: usually use good thermal conductivity of metal materials, such as aluminum alloy, stainless steel or copper, these materials not only have good thermal conductivity, but also corrosion resistance.

Inquiry

Inquiry

One-piece water-cooled motor casing

Material Selection: Usually good thermal conductivity of metal materials, such as aluminum alloy, stainless steel or copper, these materials not only have good thermal conductivity, but also have corrosion resistance.

Inquiry

Inquiry

One-piece water-cooled motor casing

Precision processing and testing: CNC numerical control processing technology and friction welding technology are adopted to ensure the accuracy of each part of the shell, and the airtightness and reliability are checked by non-destructive testing means (e.g. ultrasonic testing, pressure testing, etc.).

Inquiry

Inquiry

One-piece water-cooled motor housing

Industrial automation equipment: In the factory automation production line, the motor needs to run efficiently for a long time, the water-cooled motor housing can provide stable heat dissipation to ensure the stable operation of the equipment.

Inquiry

Inquiry

Aluminum intercooler housing is an important accessory for turbocharged engine, the main role is to reduce the temperature of the air after supercharging, so as to reduce the heat load of the engine, improve the efficiency of air exchange, and increase the output power of the engine.

Inquiry

Inquiry

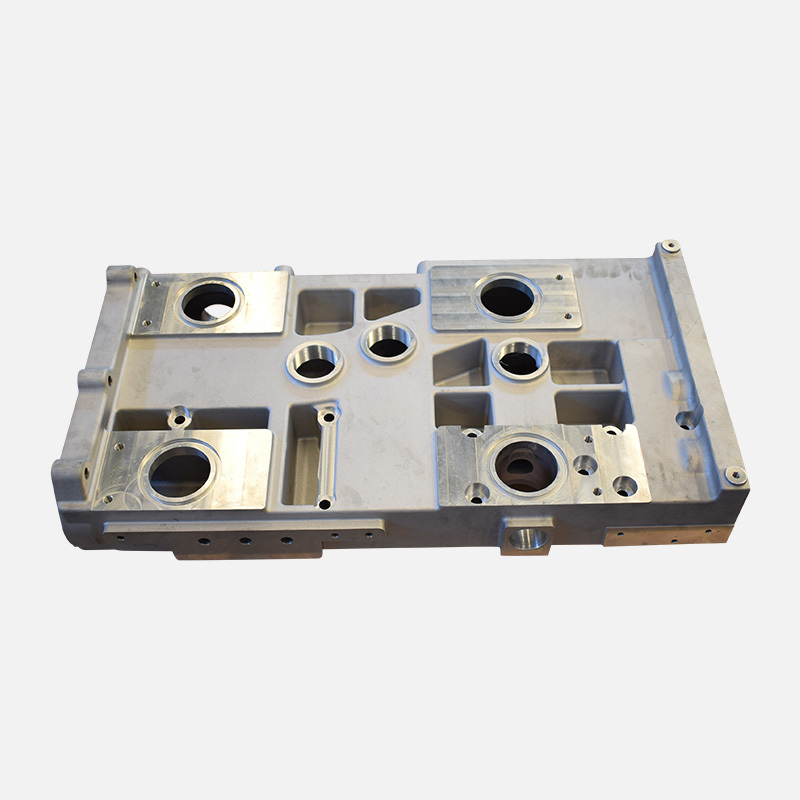

Aluminum alloy transmission housing is a commonly used component in modern automobile manufacturing, mainly used to carry and protect the mechanical parts inside the transmission to ensure its normal operation.

Inquiry

Inquiry

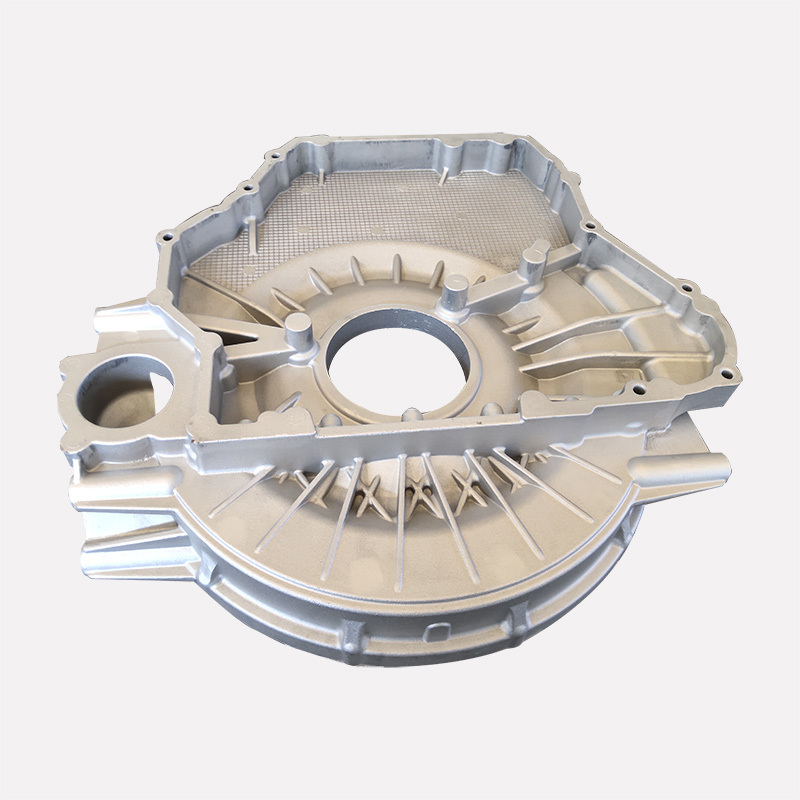

Aluminum alloy flywheel shell is a kind of mechanical parts made of aluminum alloy, mainly used to cover the flywheel and clutch outside, play a protective and supportive role.

Inquiry

Inquiry

Casting process: It is suitable for large and complex shell structure, with good mechanical properties and dimensional stability, commonly used in the manufacture of heavy-duty gearbox shells.

Inquiry

Inquiry

Die casting process: Molten aluminum alloy is injected into the mold through high pressure to form a shell with high precision and high surface quality. Die casting aluminum alloy is high strength, light weight and dimensionally stable, which makes it suitable for manufacturing complex shaped gearbox housings.

Inquiry

Inquiry

High-performance aluminum alloy: such as 6061 aluminum alloy and 7075 aluminum alloy, commonly used in the field of new energy vehicles. These materials have higher strength and better corrosion resistance, ensuring performance while reducing weight and improving energy efficiency.

Inquiry

Inquiry

5052 aluminum plate: lightweight, easy to process, corrosion resistance and environmental protection advantages. 5052 aluminum plate is suitable for automotive lightweighting needs, high elongation, easy to stamping and welding, strong resistance to marine atmospheric corrosion, and high recycling rate.

Inquiry

Inquiry

ADC12 die-casting aluminum alloy: belonging to Al-Si-Cu series, with silicon content between 9.6% and 12.0%, it has excellent casting and pressure resistance, and is suitable for manufacturing complex castings. Its high strength, good pressure resistance, thermal brittleness is small, but the corrosion resistance is slightly worse.

Inquiry

Inquiry

Light weight: The lower density of aluminum alloy makes the aluminum alloy motor housing lighter than traditional iron or cast iron motor housings, making it easier to install and transport.

Inquiry

Inquiry

Get a Free Consultancy

Please leave your contact information and we will arrange for an expert to contact you.